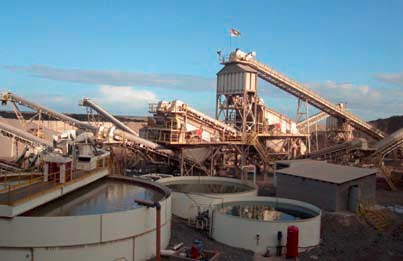

UTE Torres Dam

Description of the Environmental Measure

Problem detected:

Due to the materials and location, it was found to be likely that on dry, windy days the aggregatecrushing plant in the Aboño industrial area would raise dust, although this would not disturb nearby urban areas.

The dust would be created by limestone crushing and sifting operations.

Solutions adopted:

Various actions were taken to minimise dust emissions.

First, the conveyor belts and aggregate sifters were fi tted with cowlings.

Also, a dry-mist dust suppression system was installed. Using this system, airborne dust particles adhere to water droplets until they become heavy enough to fall onto the processing line. Unlike other misting systems, the system installed on this site needs very little water and does not wet the material— it merely dampens the dust. Moreover, it needs no additives or chemicals. The reason why the system is so effi cient is that it can generate water particles just a few microns in size, similar to the size of the dust particles that are to be eliminated.

Moreover, the dampening systems at the end of the belt, for the middle cone and the sand, were backed up by several water sprayers installed to complement the DSI system’s sprayers. On the sand belt, to optimize the aggregate-dampening process, the sprayers were fi tted with cowls to protect them from the wind and, therefore, avoid dispersion of the water spray.

Results:

The results were optimal in all cases, and dust emissions were minimised.